By offering in-house high definition plasma cutting on our state-of-the-art CNC equipment, Atlantic Stainless provides customers with an economical alternative to expensive water-jet cutting and saves them valuable machining time and costs.

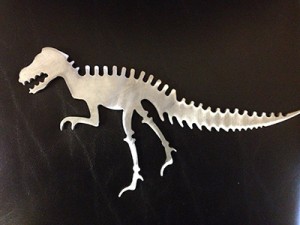

We are often asked how the plasma cutting process works. Using a high-temperature, high-velocity stream of ionized gas, 2D shapes are cut from thick pieces of sheet metal. The plasma stream is generated by directing the flow of an inert gas where an electric arc ionizes the gas. The material is then heated to a molten condition and the high-velocity gas stream blows the material away. To see the CNC equipment in action, check out a video of our plasma cutting experts working on a project.

This process offers solutions to a range of applications across industries. Below we explain what some of the advantages of plasma cutting are, which industries it is typically used in, and offer design recommendations.

Advantages of Choosing Plasma Cutting Services

Whether it is cutting simple shapes or complicated drawings, our high definition plasma system will save you both time and money. Our fully computerized system takes your CAD or other drawings and integrates them into our system for easy, accurate cutting.

Applications and Design Considerations

Our customers range from the construction industry to food preparation services, so we provide services for various industries and applications. Atlantic Stainless offers high definition plasma cutting on 304L, 316L, 303, 430, 17-4 and many other stainless steel grades. The system can handle relatively thin sheet (up to 6” thick and 8’-20’ long), making it a good tool for products like countertops and food equipment requirements. It can also handle stainless steel plate as thick up to 2” or heavier, allowing machine shops and fabricators a good, clean product for the manufacturing of their parts.

At Atlantic Stainless, we stock a wide variety of materials, use state-of-the-art machines and diligently follow all design specifications sent to us by our clients. We continually strive to improve and optimize our processes while maximizing customer convenience. Request a sample or request a quote for your next project.