Polished stainless steel and satin stainless steel are specific surface finishes available for a variety of stainless steel applications. Though both finishes are a result of a particular stainless steel polish method, they are, in fact, secondary operations necessitated to change the dull gray, “mill finish” appearance when stainless steel leaves the steel mill. Such stainless steel polish methods serve a number of purposes, from increasing protection from surface wear and corrosion to improving the material’s aesthetic appeal. (more…)

News

Stainless Steel Sensitization: What It Is & How to Prevent

Stainless steel is one of the world’s most recognized and widely used materials. Though known for its anti-corrosive properties, it is susceptible to sensitization, a type of corrosion, during welding fabrication processes. Knowing how to prevent stainless steel sensitization during those processes can help ensure the material retains its anti-corrosive properties. (more…)

How Stainless Steel Tubing is Made

Stainless steel is a versatile steel alloy comprised of a percentage of chromium, which provides the material its corrosion resistance and the trait that gives stainless steel its name. There are many grades of stainless steel, but all must have a minimum chromium content of at least 10.5 percent and can range upwards of 20 percent depending on the application’s needs. The material is known for its excellent oxidation resistance, durability, and low maintenance, which is why it is widely used in producing a large and diverse array of parts and components in many industries. This makes understanding stainless steel tube fabrication an essential part of the purchasing process. (more…)

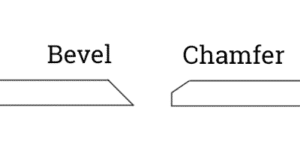

Bevel vs. Chamfer Edges: Differences and Applications Explored

Seamless vs. Welded Tubing: What’s the Difference?

Seamless vs. welded tubing represent two different types of stainless steel tubing used in various industrial and commercial construction, structural, medical, and aesthetic applications. Therefore, choosing between seamless vs. welded tubing will depend on the product application requirements. Though seamless and welded stainless steel tubing are common forms of tubing, they differ in a number of ways. Users should be aware of these primary differences, including the following: (more…)